MOLDINO - TD4N type : Radius Mill TD4N | JSR GROUP

October 24, 2025

TD4N type

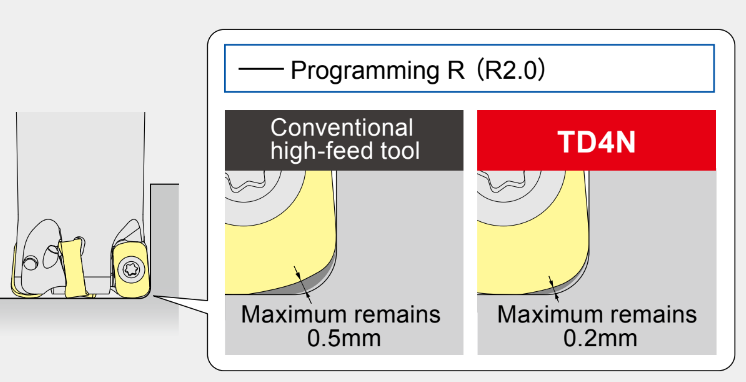

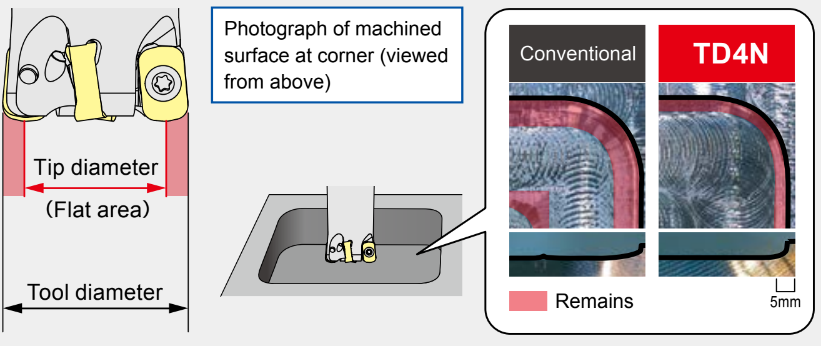

| Features | 01 | Reduces uncut remnants on work pieces |

The cutting edge shape was reviewed for TD4N so that remains are reduced.This enables the load on the next process to be reduced by up to 40% compared to conventional products. |

|

| Since it is difficult to create tool shape definitions in CAM for the complicated cutting edge shapes of high-feed tools, in many cases the tools are used with the definition for a simple R radius tool. The differences between this definition and the actual tool shape result in remains that cannot be checked on CAM and become more work for the next process. |  |

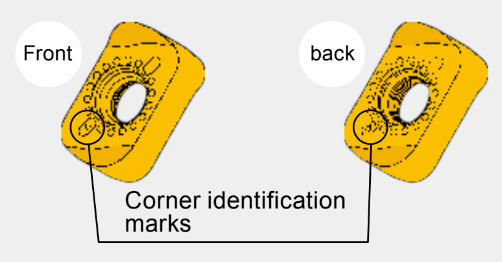

| Features | 02 | Economical 4-corner inserts with chip breakers for various applications |

| By making it possible to use both the front and back sides of inserts, 4 corners can be used. The inserts are provided with a large rake angle which exhibits an excellent cutting force reduction effect even when compared to general positive-shape inserts. |  |

|

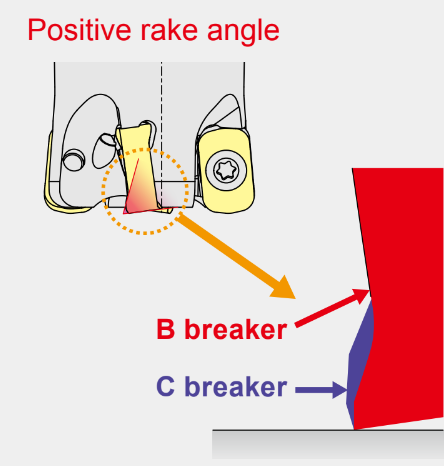

| Features of insert breaker | ||

|

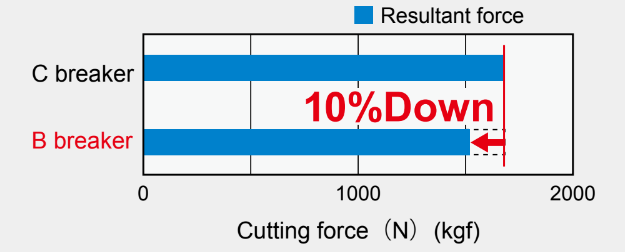

C breaker Corresponds to our general high-feed-type inserts (EDNW, EPNW, WDNW, SDNW), and is resistant to chip jamming, vibrations, and crater wear. B breaker Enables reduced cutting force when cutting work materials such as stainless steels, etc. that require free-cutting performance. |

|

|

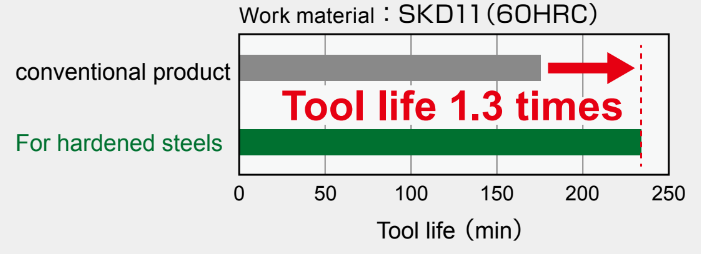

| Features of insert for high-hardness materials | ||

| High-precision G-class insert suppresses dispersion in tool life.Employs JP4105, a grade for high-hardness materials which provides long service life for machining 50HRC or harder matrials. | ||

| Comparison of cutting force | Tool life comparison with conventional products | |

|

|

| Features | 03 | Large tip diameter for excellent handling |

| Compared to conventional high-feed tools, TD4N has a large tip diameter, which suppresses the generation of remains which easily occur on the bottom surface of machined areas. In addition, since the cutting width (ae) can be set to a large value, this is also effective for improving machining efficiency. |  |

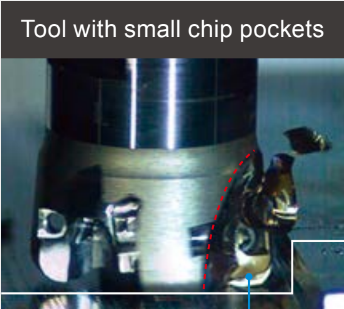

| Features | 04 | Excellent chip discharge characteristics |

| Reduces the occurrence of sudden problems due to jamming of cutting chips. In addition, good chip removal makes it possible to further improve cutting performance. | |

|

Crushed cutting chips If cutting chips are not discharged well, jamming of the cutting chips between the tool and wall occur, which can become the cause of sudden damage such as chipping, etc. |

Cutting chips which were discharged well Good chip discharge characteristics are achieved by providing large chip pockets and controlling the chip discharge direction. |

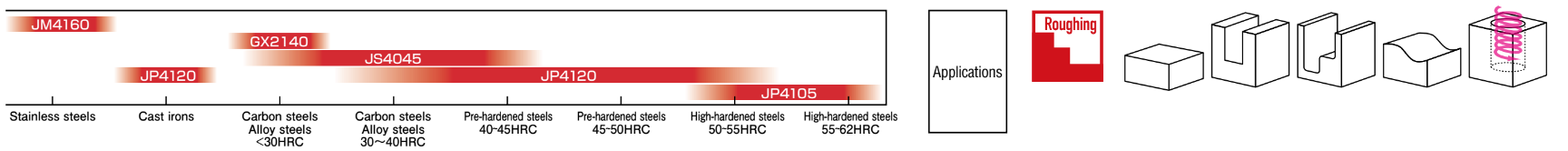

| Features | 04 | Lineup of insert grades |

| PVD Technology | Grade for machining high-hardness materials JP4105 |

| ・Employs an ultra-fine cemented carbide substrate and the new "AJ Coating" to improve wear resistance. ・Excellent wear resistance when machining high hardness materials of 50HRC or higher |

|

| PVD Technology | Grade for machining pre-hardened or hardened materials JP4120 |

| ・Employs a fine carbide substrate with an excellent balance between wear resistance and toughness and the new "AJ Coating" to provide improved wear resistance and chipping resistance. ・Highly versatile with excellent wear resistance and chipping resistance when machining steel materials with hardnesses of 30 to 50 HRC. |

|

| PVD Technology | Grade for machining stainless-steel materials JM4160 |

| ・Employs a carbide substrate with high toughness and the new "AJ Coating" to improve wear resistance and chipping resistance when machining stainless-steel materials. ・ Reduces the welding to work material that occurs when machining stainless steel materials. |

|

| PVD Technology | General purpose for steel JS4045 |

| ・JS4045 adopts heat resistant layer, reduces the crater wear by high-speed cutting. ・JS4045 adopts heat resistant substrate, reduces the wear and improves tool life. ・Improves tool life on dry cutting. |

|

| CVD Technology | General purpose for steel GX2140 |

| ・Smooth surfaced α-Al2O3 layer with improved chipping / welding resistance brings less sudden-tool-edge-chipping. ・Machining efficiency is improved for high-speed,high-feed-rate rough machining by using the layer with fine columnar structure. |

|